Tapping, Testing & Casting

As we are a craft foundry from the apprentices to the skilled, training is given in all aspects of casting production, from moulding, shot blasting, melting, casting.

Contact us01484 428203The Tapping Hole

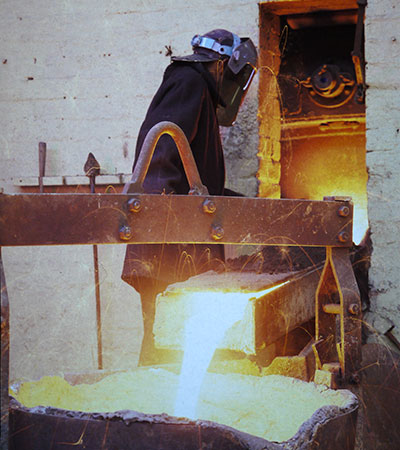

At the bottom of the cupola is the tapping hole. This is where the iron is removed from the furnace. The hole is made about 40-45 mm diameter and is sealed with a clay bod. The bods can be seen attached to rods hanging off the wall on the left. When the molten metal has filled to around 600 kgs, the hole is opened by breaking the clay. The metal flows down the trough and into the ladle. The ladle shown holds 2 tonne and is removed to the moulds by a crane. When all the metal from 1 batch is out the hole is closed using a new clay body.

Tapping the Cupola

Testing

To test the metal to see it's grade and whether an adjustment is needed to the composition we take a sample of metal from the stream when it is tapped from the furnace.

Additions will comprise of silicon and graphite to 'seed' the iron crystals to promote a fine-grained iron. The sample is cast into a wedge shaped mould 150 mm long.

The test sample is removed from the mould as quickly as possible and whilst still glowing is chilled in water. This is for us to see the effect the additions have on the cooling rate and the formation of 'grey' iron with free graphite, which is easily machined and chilled iron ' white' which is a carbide and hard to machine.

The sample is about actual size and shows if we were to cast a casting thinner than 8-10 mm with this metal the iron would cool white and be too hard to machine. Above that thickness the casting will be grey with free graphite giving a natural lubricant to aid machining.

Sampling the molten metal

The Sample

The test sample is removed from the mould as quickly as possible and whilst still glowing is chilled in water. This is for us to see the effect the additions have on the cooling rate and the formation of 'grey' iron with free graphite, which is easily machined and chilled iron ' white' which is a carbide and hard to machine.

The sample is about actual size and shows if we were to cast a casting thinner than 8-10 mm with this metal the iron would cool white and be too hard to machine. Above that thickness the casting will be grey with free graphite giving a natural lubricant to aid machining.

Quenching the sample

The Cast

When we have sufficient metal of the right grade. The ladle is taken by crane to the mould. When the temperature is right it is poured in to the mould.

Casting being poured