Melting

To create molten metal we use two methods; Cupola (Blast Furnace) and Electric Furnace

Contact us01484 428203Cupola (Blast Furnace)

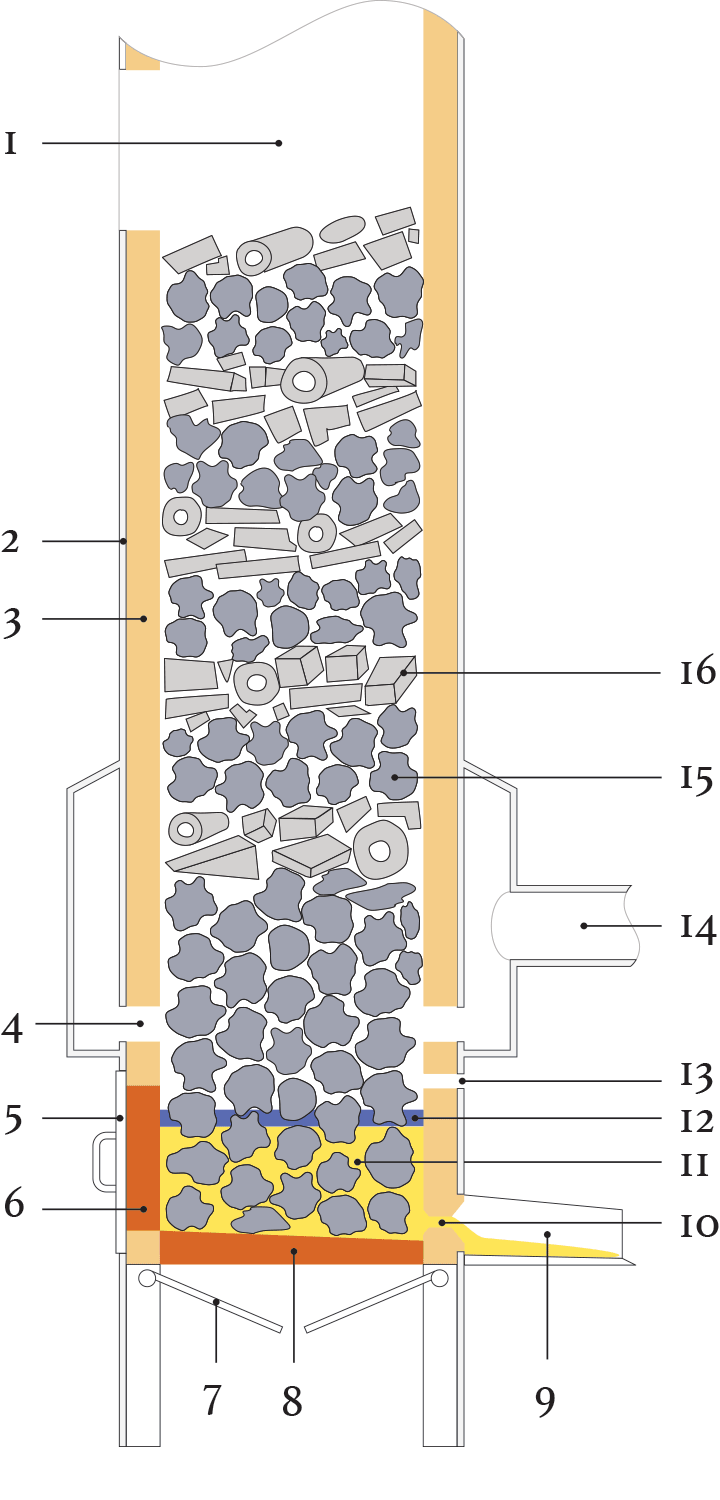

A blast furnace is the oldest method of melting iron, known as a cupola where a bed of coke is ignited. The coke we import from Poland, it is about 150 mm cube in size and we use around 10% weight of metal to melt with.

- Above, where the air comes into the furnace, are layers of coke and metal.

- Air is forced into the furnace through vents (Tuyeres) and oxygen in the air super heats the coke to above 1500oC.

- Heat travels up the furnace and melts the layer of metal above the coke.

- Metal melts and flows down through the coke into the well at the bottom.

- When one layer of metal is melted the next layer of coke drops down and melts the metal layer above.

- New metal is charged at the top

- Molten iron is created at 3 tonnes/hour

When there is sufficient metal in the well below the tuyeres it is removed through the tapping hole, flows down a trough and into the ladle. The tapping hole is then bodded with a piece of clay on the end of a rod, which in turn is removed when more metal is collected.

To stop the shell from melting when the heat is on, ceramic bricks, forming a circle, are used to line the inside of the furnace building up to form an internal chimney. This in turn is sealed by ganister, a clay and aggregate mixture used to fill the cracks between the bricks and is applied daily to repair the wear and tear

Metal, when it is molten, stills weighs the same, so the head pressures can squeeze the liquid through the tiniest of gaps. This can then weaken the outer shell allowing the extremely hot metal to cut through the thin outer shell, like the proverbial hot knife through butter. We take all precautions to ensure the furnace is sealed and have an effective method developed in case of emergencies.

- Metal and Coke loaded in

- Steel casing

- Brick lining

- Tuyeres

- Service door

- Sand

- Swing doors

- Sand base

- Trough

- Tapping Hole, metal out

- Molten metal

- Layer of Slag

- Slag Hole

- Blast air in

- Coke

- Recycled Iron

Recycled Iron

Recycled metal parts used for melting

Scrap metal consisting of old brake drums, engine blocks and other quality produced parts are supplied in sizes suitable for handling. Metals such as aluminium are removed from the scrap as it may cause gas holes in the finished castings. Copper left in will strengthen the metal.

Charging the Cupola

Coke to fuel the furnace

The materials for charging include steel to dilute carbon and silicon levels, coke for melting, pig iron for increasing the silicon level, manganese for reducing sulphur in the iron and limestone for balancing the acidity of liquid contents as the iron melts through the coke while also increasing the fluidity of the slag.

The Slag Hole

Air blasting through slag hole

Slag floats on the top of the metal, as the metal level rises the slag pours out through a hole 700 mm above the base of the furnace. The picture shows just the air blast coming out of the slag hole before the slag reaches that level.

Electric Melting

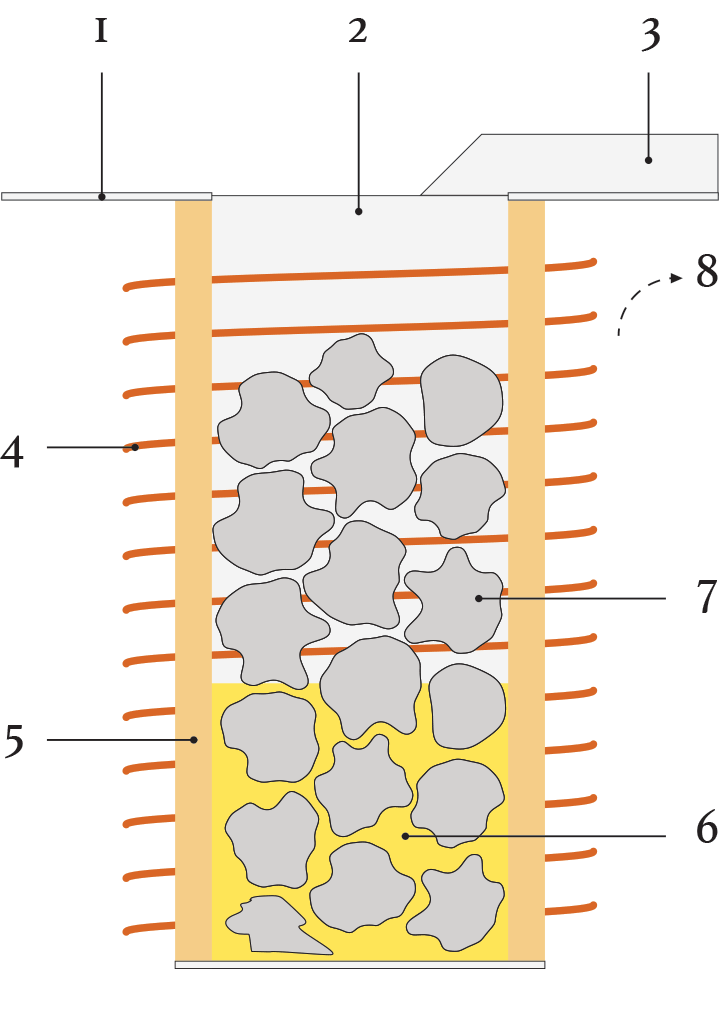

This is more like cooking and gives a greater control of the metal chemistry than with cupola melting. What you put in you can get out, with predictable losses of certain elements. It is more suitable for producing SG and Nickel Irons.

The material is loaded into a ceramic pot. Electrical coils surrounding the pot induce a frequency into the metal causing excitation of the molecules. Temperature increases causing the iron to melt. Cooling water coils surround the pot to stop the coils from melting.

Similar to the cupola the the electric furnace is constructed with an internal chimney and lined with a ceramic powder which is fused into position to form a pot. Our electric furnaces are raised above ground level for ease of filling, a platform for material storage and instruments surround the furnaces

When the metal has reached the correct chemistry and temperature the whole floor and pot section is tilted forward to pour the metal into ladles attached to craneage. The ladles are then taken to various moulds for casting.

- Ground level

- Opening

- Trough

- Electric & cooling coils

- Ceramic lining

- Moltern metal

- Metal to be melted

- Crucible tilted 90°, moltern metal poured out

New Electric Furnace

Melting iron in the Electric Crucible

Floor and pot tilted to pour the metal